What kinds of laser cutting machines are there?

According to the different laser generators, laser cutting machines on the market can be roughly divided into three types: CO2 laser cutting machine, YAG (solid state) laser cutting machine and optical fiber laser cutting machine.

I: CO2 laser cutting machine

CO2 laser cutting machine can stably cut carbon steel within 20 mm, stainless steel within 10 mm and aluminum alloy below 8 mm. The wavelength of CO2 laser is 10.6um, which is easy to be absorbed by nonmetallic materials. It can cut wood, acrylic, PP, plexiglass and other nonmetal materials with high quality. However, the photoelectric conversion rate of CO2 laser is only about 10%. The CO2 laser cutting machine is equipped with a nozzle for injecting oxygen, compressed air or inert gas N2 at the beam exit to improve the cutting speed and the smoothness of the incision. In order to improve the stability and life of the power supply, the discharge stability of high-power laser should be dealt with for CO2 gas laser. The damage grade of laser is divided into 4 grades, and CO2 laser is in the first grade.

Main advantages: high power, general power between 2000-4000w, can cut stainless steel, carbon steel and other conventional data within 25 mm, aluminum plate within 4 mm and acrylic plate within 60 mm, wood data board, PVC board, and the speed is very fast when cutting thin plates. In addition, because the output of CO2 laser is continuous laser, the cutting section effect of the three laser cutting machines is very lubricating.

The main market positioning: 6-25 mm plate cutting processing, mainly for large and medium-sized enterprises and some pure external processing laser cutting processing enterprises, but because of its laser protection loss, host power consumption and other factors can not be overcome, in recent years, by the huge impact of fiber laser cutting machine, the mall is in a significantly shrinking state.

Second, YAG laser cutting machine

YAG solid-state laser cutting machine has the characteristics of low price and good stability, but the energy power is generally low-3%. Now the output power of the products is mostly below 600W. Because of the small output energy, it is mainly used for drilling, spot welding and sheet metal cutting. Its green laser beam can be used in the case of pulse or continuous wave, with wave length and good concentrating property, which is suitable for fine machining, especially for hole machining under pulse. It can also be used for cutting, welding and photolithography. The laser wavelength of YAG solid-state laser cutting machine is not easy to be absorbed by non-metal, so it can not cut non-metallic data. What YAG solid-state laser cutting machine needs to deal with is to improve the stability and life of power supply, that is to develop large capacity, long-life optical pump to encourage light source, such as the use of semiconductor optical pump can greatly increase the energy power.

Main advantages: it can cut aluminum plate, copper plate and most non-ferrous metal materials that can not be cut by other laser cutting machines. The purchase price of the machine is cheap, the use cost is low, and the protection is simple. Most of the key skills have been mastered by domestic enterprises. The price and protection cost of accessories are low. The machine operation and protection are simple, and the requirements for the quality of workers are not high.

The main market positioning: cutting below 8mm, mainly for self-use small and medium-sized enterprises and processing requirements are not particularly high for most of the sheet metal production, home appliances production, kitchenware production, decoration, advertising and other professional users, gradually replacing wire cutting, CNC punch, water cutting, low-power plasma and other traditional processing equipment.

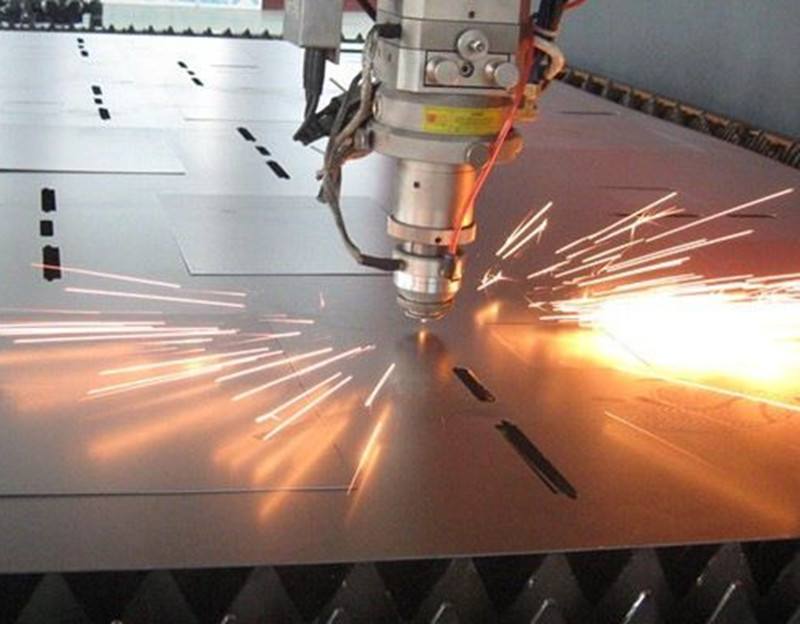

3. Fiber laser cutting machine

Fiber laser cutting machine because it can be transmitted through optical fiber, flexible degree of progress, less defects, convenient protection, speed is very fast, so in cutting thin plate within 4mm, fiber cutting machine has great advantages, but affected by the wavelength of solid laser, it is poor quality in cutting thick plate. The wavelength of fiber laser cutting machine is 1.06um, which is not easy to be absorbed by nonmetal, so it can not cut nonmetal data. The photoelectric conversion rate of fiber laser is as high as 25%, and the advantages of fiber laser in power consumption and cooling system are obvious. The laser damage level is divided into 4 levels. The fiber laser has a large damage to the human body because of its short wavelength, and it belongs to the level 1 with greater damage because of its short wavelength. As a new laser skill, fiber laser cutting machine is far less popular than CO2 laser cutting machine.

Main advantages: high photoelectric conversion rate, low power consumption, can cut stainless steel plate and carbon steel plate within 12mm. It is the laser cutting machine with very fast cutting speed in the three kinds of machines. The slit is small and the spot quality is good. It can be used for fine cutting.

The main market positioning: cutting below 12mm, especially the high-precision processing of thin plate, is mainly aimed at the manufacturers with very high requirements on processing precision and power. It is estimated that with the emergence of laser with 4000W and above, fiber laser cutting will replace most of the high-power CO2 laser cutting machines.

Laser cutting machine, is the end of the last century, the beginning of this century, a new type of plate processing machinery equipment. Through the continuous skill updating and process development at home and abroad in the past 20 years, laser cutting technology and laser cutting machine equipment are being understood and accepted by broad plate processing enterprises, and gradually replace plasma cutting, water cutting, flame cutting, numerical control punch, etc. with its advantages of high processing power, high processing precision, good cutting section quality and 3D cutting processing Traditional plate processing methods.

After 20 years of development, according to different laser generators, laser cutting machines on the market can be roughly divided into three types: CO2 laser cutting machine, YAG (solid state) laser cutting machine and fiber laser cutting machine.

Source: Jiangmen laser cutting http://dxcpx.cn/index.html

-

11-14

What are the functional features of stainless steel plate?

Analysis of functional characteristics of stainless steel plate: 1. Corrosion resistant stainless steel plate has similar ability to resist general corrosion as unstable NiCr 304. Long time heating in the temperature scale of chromium carbide may affect the corrosion resistance of alloys 321 and 347 in harsh corrosive media. It is mainly used at high temperature, which requires strong sensitization resistance to prevent intergranular corrosion at lower temperature. 2. High temperature oxidation

-

11-14

Four factors affecting the coating of stainless steel plate

There are four kinds of factors that affect the coating of stainless steel plate: first, the connotative factor of stainless steel plate. What we all know is that the low nickel content in stainless steel makes the passivation function of stainless steel low. Therefore, the content of martensite and chromium and nickel in stainless steel has great influence on the passivation function of stainless steel plate. Second, stainless steel plate uses the medium in the environment. In thermodynamics, t

-

11-14

What are the materials that cannot be cut by fiber laser cutting machine?

People who have a certain understanding of the fiber laser cutting machine should know that its use scale is very wide, and the cutting effect is also very good. But fiber laser cutting machine is not what kind of material can be cut, there are some materials on the fiber laser cutting machine damage is relatively large, so can not use the fiber laser cutting machine to cut. Although the fiber laser cutting machine has many excellent characteristics, it is not invincible. There are still many da

-

11-14

What kinds of laser cutting machines are there?

According to the different laser generators, laser cutting machines on the market can be roughly divided into three types: CO2 laser cutting machine, YAG (solid state) laser cutting machine and optical fiber laser cutting machine. One: CO2 laser cutting machine, CO2 laser cutting machine can stably cut carbon steel within 20 mm, stainless steel within 10 mm, and aluminum alloy below 8 mm. The wavelength of CO2 laser is 10.6um, which is easy to be absorbed by nonmetallic materials. It can cut woo