Brief introduction of surface processing of stainless steel plate

Now, many kitchenware, door factory, elevator factory, furniture factory, decoration company use a lot of stainless steel plate. Well, a large part of it has been processed. Some brief introduction of some decoration stainless steel plate (cold rolled stainless steel plate) surface treatment processing to do a brief introduction.

When stainless steel comes out of a large steel plant, it is rolled in a whole coil, which looks like fog, commonly known as 2B surface; there is also a kind of Ba surface, whose brightness is generally called 6K. So we see a variety of colors, stripes, shapes of stainless steel plates are processed out of late. The width of steel coils in large steel mills is limited, one is 1219mm, the other is 1000mm, and the other is 1500mm. Therefore, there are no 1800mm wide and 1900mm long stainless steel plates in the market.

Surface finish:

1. Mirror (also known as 8K): mirror is the same mirror made of stainless steel plate polished by machine, and the light shines on people. Stainless steel rolls can also be mirror treated.

2. Wire drawing, snowflake sand and general sand: wire drawing, snowflake sand and general sand are also collectively referred to as frosting. The three kinds of stainless steel are called different because of their different sand patterns. The sand grain of wire drawing is very thick and long, followed by general sand, and the sand grain of snowflake sand is very small. Of course, their processing machines are not the same. But now there are also manufacturers who need to make the appearance of mixed sand, that is to say, first grind the snowflake sand, and then do the drawing. Stainless steel coil can also be processed in this way. Pay attention to 1001 degree micro signal: bailingyidu88

The above two belong to the basic processing.

3. Sand blasting: that is to say, the surface of stainless steel plate presents fine bead sand surface. However, stainless steel sandblasting is divided into matte sandblasting and bright sandblasting. Matte means sandblasting when the plate is still 2B, and the bright light is after grinding the mirror. In theory, stainless steel coil can be used for this kind of processing, but there is no such production machine now. Pay attention to 1001 degree micro signal: bailingyidu88

4. Random pattern: also known as harmony pattern. The surface of the stainless steel plate after processing will present a circle of sand lines from a distance, and from a near point, it is irregular random lines.

5. Embossing, also known as embossing, is that we see the appearance of small diamond, cube, square, panda pattern, such as stainless steel plate. But when we go to do processing, we use coiled material to do it. We can't do this kind of processing with a sheet of 4 * 8 feet. We need to emboss and then go to the flat plate, then we can see the stainless steel plate with stripes.

6. Titanium plating: what many people call colorful stainless steel is actually the plate with certain color on the surface after titanium plating treatment, such as yellow titanium, rose gold, sapphire blue, etc. Titanium plating needs to use the machine called titanium furnace, do color time in the above five kinds of pre-processing plate can be colored, but embossed stainless steel stripes out, but also use 8K machine to grind into 6-8k effect before going on color. There is still a little demand in titanium plating. What is proposed is to make black titanium, which can be done with titanium furnace. But now, the most common way is to coat black titanium with water. According to a certain proportion, the potion is prepared, and then the plate is put into the potion pool. Through electrolysis, the appearance of stainless steel is black. Generally speaking, the effect of water plating black titanium is better than that of vacuum plating. So many people call the rose gold stainless steel, or titanium plate.

7. Etching: chemical agents are used to make the surface of stainless steel uneven, maybe some words and pictures. Generally, the etched plates are processed in the early stage, which can be used to make color first and then to etch, and also to etch first and then to make color. The etched stripes can be etched according to the pictures or words required by customers, and the back of the etched plate has no trace of front stripes.

8. Titanium removal: some people call the plate after titanium removal as colorful stainless steel. Titanium stripping is literally, first plating titanium gold on the plate, and then in a designated part of the color to a specific spot, shape.

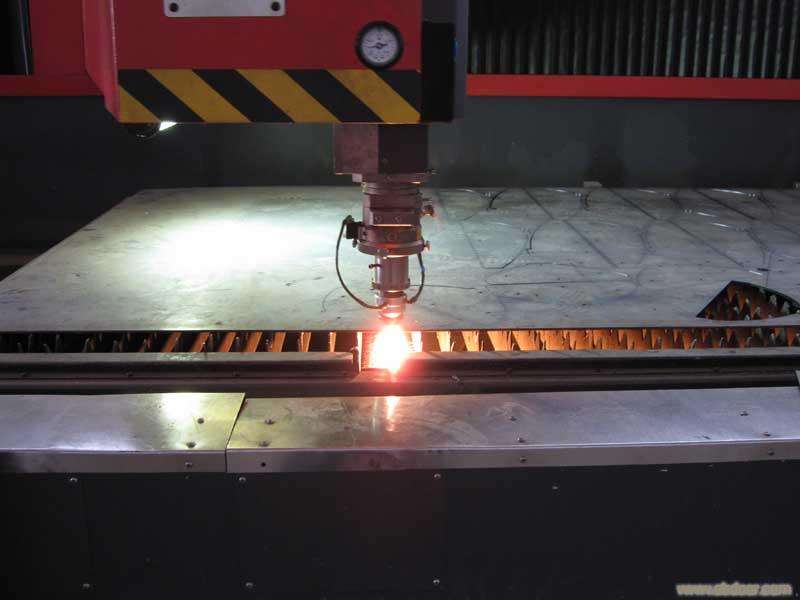

Laser: this technology is now used in many fields. But detailed processing manufacturers are now confidential.

10. No fingerprint: a layer of oil is attached to the surface of stainless steel plate and dried to prevent fingerprint and oxidation.

11. Colorful stainless steel. The colorful stainless steel in the stainless steel industry refers to drawing on the surface of stainless steel which has been treated basically. Different from titanium, etching, embossing. It's entirely up to the client to determine. For example, customers can choose to do "Qingming Riverside", perhaps a color that titanium can't do. The board made of this technology has the same appearance as over molding, and the color stripes are also used for a long time.

12. Laminating board: it is to composite the printed and pasted products to the surface of stainless steel plate by pasting, which can produce very beautiful pictures and stripes.

13. Copper plating, stainless steel surface copper plating. Some customers said that the demand is only to do copper color, then choose to do titanium gold plated bronze. There are also many customers who want to make the plate old and antique, so we need to make water plated bronze and water plated red copper. When copper plating is done, the surface can not be treated, because even if it is treated, it will be covered by copper. After copper plating, we go to make black silk, and then we have no fingerprints. When we cut the surface of this kind of plate, we can see not the natural color of stainless steel, but the color of copper.

14. Composite color board: it is compounded on the basis of these processing.

Source: Jiangmen laser cutting http://dxcpx.cn/index.html

-

11-14

What are the functional features of stainless steel plate?

Analysis of functional characteristics of stainless steel plate: 1. Corrosion resistant stainless steel plate has similar ability to resist general corrosion as unstable NiCr 304. Long time heating in the temperature scale of chromium carbide may affect the corrosion resistance of alloys 321 and 347 in harsh corrosive media. It is mainly used at high temperature, which requires strong sensitization resistance to prevent intergranular corrosion at lower temperature. 2. High temperature oxidation

-

11-14

Four factors affecting the coating of stainless steel plate

There are four kinds of factors that affect the coating of stainless steel plate: first, the connotative factor of stainless steel plate. What we all know is that the low nickel content in stainless steel makes the passivation function of stainless steel low. Therefore, the content of martensite and chromium and nickel in stainless steel has great influence on the passivation function of stainless steel plate. Second, stainless steel plate uses the medium in the environment. In thermodynamics, t

-

11-14

What are the materials that cannot be cut by fiber laser cutting machine?

People who have a certain understanding of the fiber laser cutting machine should know that its use scale is very wide, and the cutting effect is also very good. But fiber laser cutting machine is not what kind of material can be cut, there are some materials on the fiber laser cutting machine damage is relatively large, so can not use the fiber laser cutting machine to cut. Although the fiber laser cutting machine has many excellent characteristics, it is not invincible. There are still many da

-

11-14

What kinds of laser cutting machines are there?

According to the different laser generators, laser cutting machines on the market can be roughly divided into three types: CO2 laser cutting machine, YAG (solid state) laser cutting machine and optical fiber laser cutting machine. One: CO2 laser cutting machine, CO2 laser cutting machine can stably cut carbon steel within 20 mm, stainless steel within 10 mm, and aluminum alloy below 8 mm. The wavelength of CO2 laser is 10.6um, which is easy to be absorbed by nonmetallic materials. It can cut woo